09/27/2024

| Topic: Technical innovations

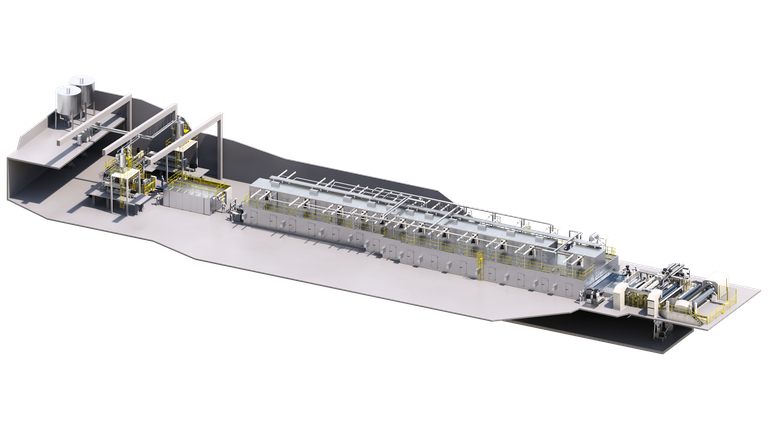

Saving energy and wear parts on the film stretching line

More energy efficient line thanks to new frequency controlled motors from DORNIER.

By using a frequency converter that precisely controls the speed of the motor, significant improvements can be achieved in terms of efficiency, performance and operating costs.

The ability to start and stop the motor smoothly increases its service life because the mechanical loads on the components are reduced.

Frequency control allows the speed and power of the motor to be adapted precisely to demand. This means that the motor only consumes the energy that is actually required. This not only reduces operating costs, but also the environmental impact.

If you have any questions, please feel free to contact us by email.